In the fiercely competitive spirits market, a distinctive custom vodka bottle can help your brand stand out. A custom bottle isn't just a product container—it's a vessel for your brand story. This article takes you through the complete design process, from initial concept to finished product.

• Discussing brand philosophy and design direction

• Creating preliminary design sketches

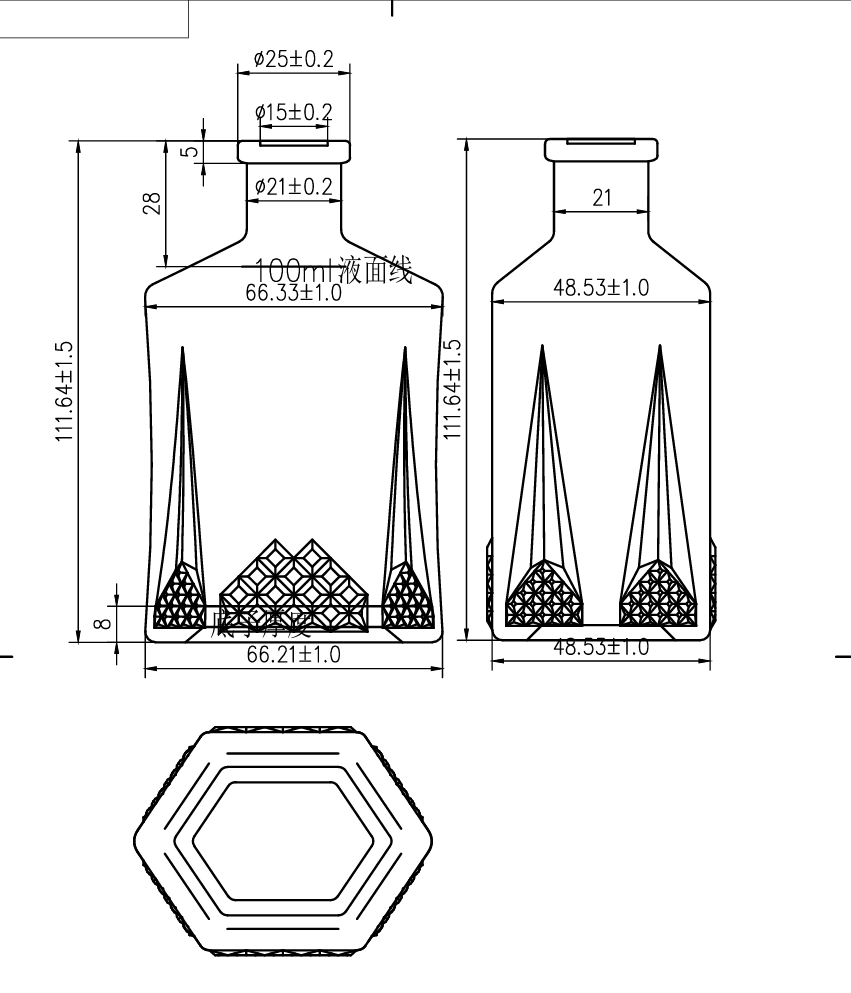

• Finalizing bottle shape, dimensions, and core aesthetic

Sketches need not be overly detailed—the focus is capturing the core creative concept. We present multiple design options for your selection, ensuring the direction is aligned before proceeding.

• Evaluate design impact from multiple perspectives

• Adjust proportions and lines

• Identify potential issues in advance

At this stage, you may request modifications, and we will refine the model until it fully meets your requirements.

• Extra flint, High flint, Normal flint

• Frosted, coating color, or electroplated finishes

• Cap materials (metal, wood, or plastic)

• Special processes like hot foil stamping, decal, or screen printing

• Verifying actual visual appearance

• Testing compatibility with packaging lines

• Assessing shipping safety

If necessary, we make final adjustments based on sample feedback to ensure flawless mass production.

• Inspecting glass purity and integrity

• Verifying printing and decoration precision

• Testing cap sealing performance

We provide regular production updates and welcome you to visit our production site.

Custom vodka bottle design represents a significant investment in brand value. Every step—from initial sketches to the final product—requires expertise and meticulous execution. Selecting the right partner ensures your design vision is flawlessly translated into exquisite, tangible bottles.

Whether launching a new brand or upgrading existing packaging, professional custom design services add distinctive appeal to your vodka offerings, helping you capture greater market attention.